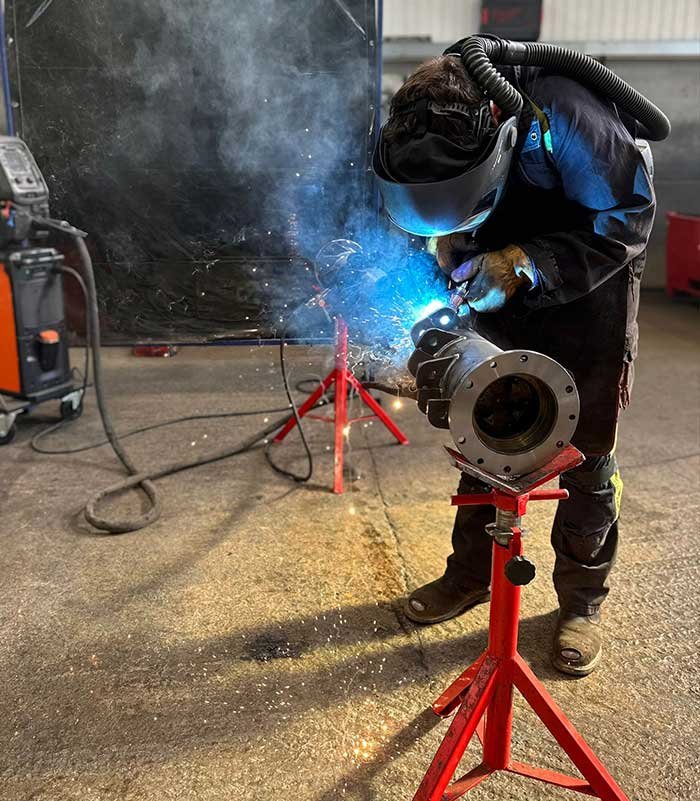

Welding & Fabrication Repairs

Welding & Fabrication Repair Services

At All Terrain Engineering, our welding and fabrication services play a critical role in the repair and preparation of components before rotor balancing. Whether you're dealing with a cracked rotor, worn shaft, or damaged frame we restore structural integrity first, ensuring your parts are ready for accurate, long-lasting balancing.

What we do

We carry out a wide range of welding and fabrication work to support the repair of cylindrical objects such as rotors:

- CRACK AND FATIGUE REPAIRS on rotors, shafts, and housings

- STEEL FABRICATION of guards, brackets, supports, and flail mounts

- WELD BUILD-UPS on worn edges prior to machining or balancing including hard facing

- CUSTOM FABRICATION for obsolete or damaged parts

- STRENGTHENING AND MODIFICATION of equipment for heavy use

Before balancing, we repair it right

Many of the rotors and components we receive for balancing are damaged or fatigued.

Our process ensures:

OUR CAPABILITIES

- MIG, TIG, and Arc Welding (Mild steel, stainless, alloys)

- CNC profile cutting

- Air Arc Gouging

- Air Arc Lancing

- CNC Folding

- In-house or on-site service available

COMMON REPAIRS

We regularly weld or fabricate parts for:

- Flail mower rotors and brackets

- Bent or cracked shafts

- Drum and roller repairs

- Fan blades and housings

- Agricultural and plant attachments