Dynamic Balancing

Dynamic Balancing

At All Terrain Engineering, we specialise in dynamic balancing for critical cylindrical components that keep your machinery running smoothly and safely. Whether it’s an industrial fan or a roller in an industrial press, precision balancing is essential to prevent vibration, reduce wear, and avoid costly breakdowns.

Unbalanced rotating parts cause excessive vibration, accelerated bearing wear, increased noise, reduced equipment lifespan and risk of mechanical failure.

Components we balance:

FLAIL HEDGE CUTTER

Used in hedge cutters and flail mowers, the rotor shafts must be perfectly balanced to avoid vibration, excessive bearing wear, and performance loss.

ARMATURES

Armatures in electric motors operate to tight tolerances. We correct imbalances that affect motor performance, vibration, efficiency, and noise levels.

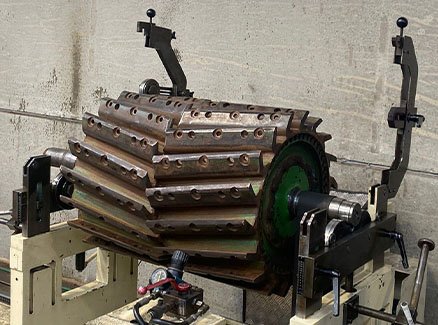

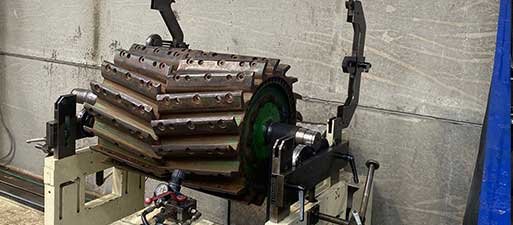

ROLLERS

Industrial rollers in printing, pressing or manufacturing must be balanced in their operation with minimal deviation. Our dynamic balancing services ensure smooth, high-speed operation of objects.

DRUMS

From rotary drums in combines and forage harvesters to wood chippers and muck spreader beaters, unbalanced drums can cause severe vibrations and operator discomfort. We repair, realign and balance these drums precisely.

IMPELLERS

Unbalanced Impellers can lead to excessive vibration leading to structural fatigue. We dynamically balance Impellers to industry standards in a swift turn around process.

FANS

We regularly carry out dynamic fan balancing and work on a wide range of fan types and styles, from fume extraction and dust extraction to blower fans.

Whats Included

1. Cylindrical Object Assessment

2. Corrective Repairs As Necessary

3. Dynamic Balancing Of The Object

4. Detailed Balance Reports

Dynamic balancing services for maintenance, repair, or new manufacturing, we ensure your components operate smoothly and safely. Fast turnaround times. Competitive pricing. Proven results.